How Does a Diesel Generator Work?

Diesel generators are vital power sources utilized in different applications, from home backup power to industrial and commercialized use. These machines allow an authentic and effective way of generating electrical energy, mainly when the power system approach is restricted or unsafe. In this article, we can go through the main definitions of diesel generator, diesel generator working principle, its components, and so on. Let’s read more to know about diesel generators.

What is a Diesel Generator?

A diesel generator is a mixture of a diesel engine and an electrical source (alternator) designed to produce electricity. Diesel generators are recognized for their robustness, dependability, and ability to deliver uninterrupted power for long hours. They are widely utilized in different sectors, including health care, telecommunications, construction, and agriculture, as well as in residential areas, for uninterrupted backup power.

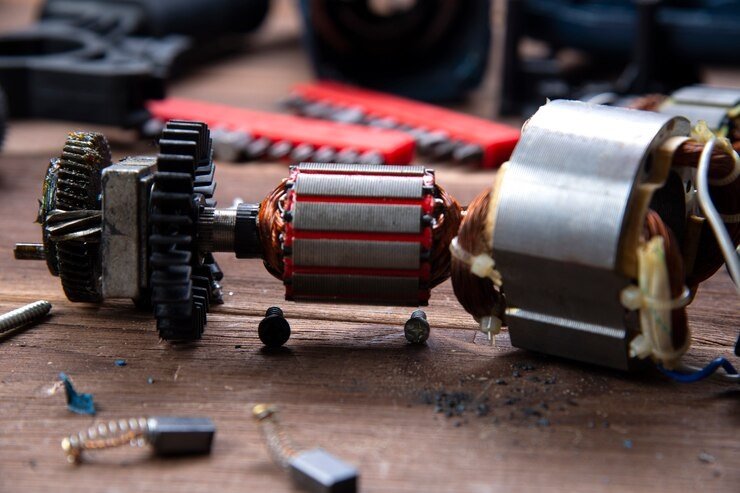

Components of a Diesel Generator:

Diesel generators consist of a lot of key components that act together to make electricity:

- Diesel Engine

- Alternator

- Fuel System

- Cooling System

- Exhaust System

- Lubrication System

- Control Panel

- Battery and Starting System

What is the Working Principle of a Diesel Generator?

The functioning of a diesel generator requires several phases, from fuel combustion to electrical energy generation:

- Fuel Injection and Combustion: The fuel injectors put Diesel fuel into the engine’s combustion chamber at high force. The compressed air in the chamber combusts the fuel, making a controlled burst. This combustion procedure begets mechanical energy by forcing the engine’s pistons.

- Mechanical Energy Changeover: The pistons rotate the engine’s crankshaft, changing the simple and rotational motions. This mechanical energy is shifted to the alternator through a pairing mechanism.

- Electromagnetic Induction: Within the alternator, the rotor coil (linked to the engine’s crankshaft) revolves within the stator coil (a fixed set of twists). The rotation of the rotor coil creates a changing magnetic flux, inducing an alternating current (AC) in the stator coil twists through electromagnetic Induction.

- Voltage Regulation: The engendered AC voltage is influenced to assure uniform power output. Voltage regulators keep up the voltage within fixed limits, protecting attached devices from power variations.

- Power Distribution: The generated electricity is then circulated to the load through the generator’s control board and distribution system. The control board supervises and adjusts to ensure the best performance.

Why Should We Need a Diesel Generator?

A diesel generator is important for offering reliable power during power grid outages and ensuring continuity in vital operations such as health care, telecommunications, and industrial procedures. It proposes a good backup solution, especially in remote areas, without an approach to the power grid. It backs up emergency preparation for homes and business organizations, safeguarding against sudden power interruptions.

Last Words:

Diesel generators are essential for offering authentic and influential power in a wide range of applications. Their strong construction, good functioning, and ability to operate for longer periods make them an important component in different industries. Realizing the working principle and components of diesel generators spotlights their importance in assuring a constant and uninterrupted power supply, especially in vital situations where authentic electrical energy is dominant.